tear test of polymer|tear resistance of pe film : manufacturer A tear test applies a force to a material that already contains a partial fracture or rupture otherwise known as a “tear” in order to bring the material to complete failure. . The more common materials that benefit from tear testing are textiles, fabrics, elastomers, rubbers, polymers, packaging and paper products. Each of these materials .

WEBParking Fury 3. Tap Tap Shots. Johnny Trigger. Soccer Skills World Cup. Battle Wheels. Papa Louie: When Pizzas Attack. Mr Bullet. Gunspin Unblocked. Play Gunspin For Free .

{plog:ftitle_list}

Se você está procurando por mulheres maduras e experientes, as acompanhantes coroas em Niteroi também estão disponíveis para proporcionar momentos de prazer .

Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method (Elmendorf Tear) ASTM D1922. Scope: A pendulum impact tester is used to measure the force required .Trouser tear testing of thin anisotropic polymer ˚lms and laminates 191 Table 2 Crack deviation in PET and laminate together with delamination due toASTM polymer and plastic test techniques: ABC: Ash Content ASTM D5630, D2584, ISO 3451; Barcol Hardness ASTM D2583; . Propagation Tear Resistance of Plastic Film ASTM D1922; Puncture Test FTMS 101C - Method 2065; QRS: QUV Accelerated Weathering - ASTM D4329, D4587, ISO 4892;A tear in a fabric or garment generally occurs progressively along a line, and can be initiated by a moving fabric being caught on a sharp object. Several methods are used to measure tear strength, e.g. double tongue rip (tear) test, trapezoid tear test, (ASTM D5587) and single tongue tear test (ASTM D2661, BS 4303).

tear resistance of pe film

polyethylene film tear strength

According to this model, the tear test of film is a special case of a high-speed stress/strain measurement performed on a polymer sample with a varying cross-section. The tear resistance of film is a function of all the parameters that characterize the stress/strain curve of the resin: stresses and strains at the yield, the necking, and the .A tear test applies a force to a material that already contains a partial fracture or rupture otherwise known as a “tear” in order to bring the material to complete failure. . The more common materials that benefit from tear testing are textiles, fabrics, elastomers, rubbers, polymers, packaging and paper products. Each of these materials .

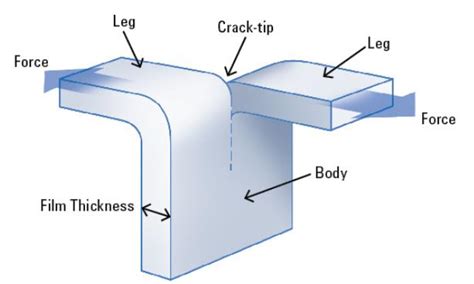

The Young’s modulus (E), Poisson’s ratio (ν), initial yield stress (σb ), work-hardening parameter (α) and film thickness for LDPE and PET in MD are presented in Table 1. 2.1 Standard trouser tear test A standard two-leg trouser tear test method (Standard 1993) was adopted to check anisotropy in the studied polymers under tearing.

This research has investigated the essential work of fracture (EWF) from trouser tear test of polyethylene terephthalate (PET), low-density polyethylene (LDPE) films and their corresponding laminate using a convenient cyclic tear test method. Propagation of tear crack in these thermoplastics deflects from the initial crack path due to the material anisotropy. An .

According to this model, the tear test of film is a special case of a high-speed stress/strain measurement performed on a polymer sample with a varying cross-section. The tear resistance of film is a function of all the parameters that characterize the stress/strain curve of the resin: stresses and strains at the yield, the necking, and the .TROUSERS TEAR TEST In accordance with AS 1683.12-2001, the trouser tear strength is the force required to propagate tear in the cut within the material divided by the material thickness. . The basic principle of the trouser tear test is shown in Figure 6. Several polymer sheets 200x100 mm in size reinforced with two and three layers of glass . The results of the industrial standard tear test, i.e., the Elmendorf tear test, are compared with those of the components of the EWF test to understand the proper empirical relationship between the Elmendorf tear test and the EWF test. . Polymer Engineering and Science, 30 (4) (1990), pp. 211-218. Crossref View in Scopus [12] R. Hill .

tear tests for tear EWF calculation, whereas, the cur-rent study showed that a single cyclic tear test can be sufficient. During a tear test, the specimen legs bends plasti-cally close to the crack tip and along the leg width in some cases. Dissipation of energy from the work done by plastic bending and straightening of trouser-legs

Tear resistance testing can be found in plastic film, paper and textile industries.Tear resistance is the measurement of a sample's ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. According to this model, the tear test of film is a special case of a high-speed stress/strain measurement performed on a polymer sample with a varying cross-section. The tear resistance of film is a function of all the parameters that characterize the stress/strain curve of the resin: stresses and strains at the yield, the necking, and the . The grip should not introduce a flaw or tear because these flaws could be an initiation point for failure, which would invalidate the test as would any failure outside of the gage length zone. . failure mechanisms or how the environmental media is interacting with or degrading a polymer test specimen. MTI Instruments Inc. has developed an in .Rubber-clay nanocomposites. A. Mohammad, G.P. Simon, in Polymer Nanocomposites, 2006 12.6.3 Tear strength. Tear strength represents the level of resistance to crack propagation in rubbers. Organically-modified layered silicates effectively enhance the tear strength of NR, EPDM, SBR, and NBR nanocomposites. 5,9,44,48,50,51,57 The excellent tear strength .

For example, with rubber, tear resistance measures how the test specimen resists the growth of any cuts when under tension, it is usually expressed in kN/m. [2] Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation.ASTM D 624 can be applied to measure the resistance to the formation of a tear . Trouser tear testing has been concerned in this research work. A polypropylene film and a low density polyethylene film used in the packaging industry are considered. The experimental trouser tear tests showed different results for both materials when they were subjected to load in different material directions. Therefore the hypothesis was verified, that .Baumann Tear Test: Often used for paper and card materials, where a central cut is made and force is applied to propagate the tear. . Application: Determines the tear characteristics of elastomers and polymers for various applications. Industries: Tires, seals, gaskets, medical equipment, etc.

pendulum tear astm

The load-extension curves for Samples A and B are shown in Figures 3(a) and 3(b), respectively. It is clearly evident from these results that it takes much lower force to tear Sample A compared to Sample B. Figure 3. Load-extension response during .

The dart impact test and the Elmendorf tear test are the two most important end-use tests of film manufactured from LLDPE and LDPE resins.[1-4,6-8] The model of the Elmendorf tear test presented .The strength of polymers is further governed by: Molecular weight The strength of the polymer rises with the increase in molecular weight. It reaches the saturation level at some value of the molecular weight. . The test specimens are in the form of a standard dumbbell shaped. For ASTM D638, the test speed is determined by the material .

the tear resistance. More specifically, they measure the force required on the test specimen to propagate a tear that has already been initiated by cutting a small notch in the specimen with a sharp blade. One of the most common tests used for measuring tear strength of films is the Elmendorf tear test.

Tensile and Trouser tear tests of thin packaging polymer films have been done successfully in this research thesis. Two different polymers (PP and . Trouser tear test, bending tests, compression tests, creep tests and several other physical test .A criterion for tearing of test-pieces cut from thin sheets of a natural rubber vulcanizate, similar in form to the Griffith criterion for spreading of a crack, is formulated. . Journal of Polymer Science. Volume 10, Issue 3 p. 291-318. Article. Rupture of rubber. . energy can be found experimentally for a particular vulcanizate and used to . Request PDF | Trouser tear tests of two thin polymer films | Trouser tear testing has been concerned in this research work. A polypropylene film and a low density polyethylene film used in the .This test method measures the volume loss due to the abrasive action of rubbing a test piece over a specified grade of abrasive sheet. The result can be reported as a relative volume loss or an abrasion resistance index. . Tear Resistance; Tensile Testing - Polymer Tensile Properties; Thermogravimetric Analysis (TGA) Torsional Testing; Volume .

Trouser tear testing has been concerned in this research work. A polypropylene film and a low density polyethylene film used in the packaging industry are considered. The experimental trouser tear tests showed different results for both materials when they were subjected to load in different material directions. Therefore the hypothesis was verified, that the in-plane material orientation .

WEBOuça Duda Lemos no Spotify. Artista · 13.3K ouvintes mensais. Artista · 13.3K ouvintes mensais. Início; Buscar; Sua Biblioteca. Playlists Podcasts & Shows Artists Albums. .

tear test of polymer|tear resistance of pe film